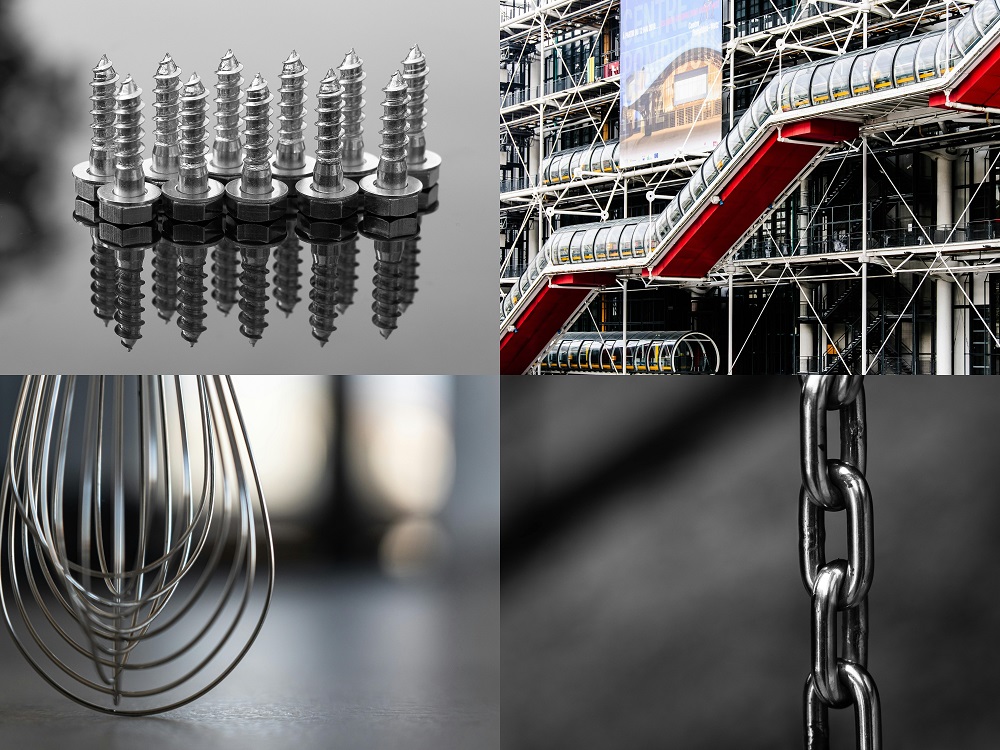

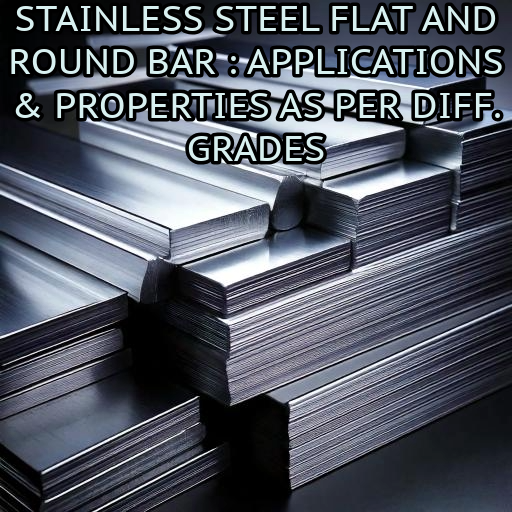

Stainless steel flat and round bars are the basic materials used in most industrial and commercial applications. Reputed for high strength, durability, and excellent corrosion resistance, these bars are quite reliable. The stainless steel alloy is basically composed of iron and chromium with other elements such as nickel, molybdenum, and manganese added to make it perform better in various functions.

The rectangular shape and uniform thickness of flat bars make them ideal for structural support and framing. They are used massively in construction, fabrication, and in the making of machinery. Used as base plates, brackets, and supports in large numbers, flat bars have smooth finishes that would also comport themselves well to the fabrication of special custom projects.

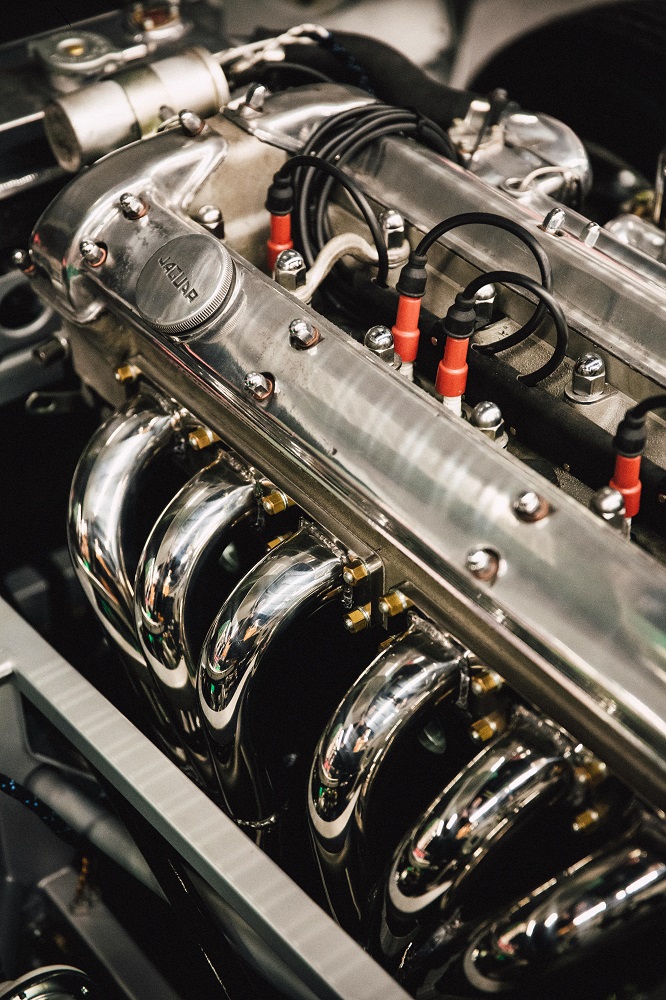

Round bars, with their cylindrical shape, can be found in an enormous number of applications, from shafts and fasteners to tools. These products are predominantly used in automotive, aerospace, and marine industries because of their high tensile strength and dimensional accuracy. Round bars come in different sizes and grades, allowing them to fit an application in a very broad range.

Stainless steel flat and round bars have very high resistance to rust, chemicals, and high temperatures. Thus, they assure reliability even in unfriendly working conditions. They have grown so versatile in the construction, oil and gas industries, power plants, and decorative projects. The eco-friendly and recyclable nature of stainless steel makes them sustainable for modern industry. Proper grade selection and processing can further improve the durability and performance of these materials, so vital for industrial and commercial applications.

Manufacturing Process of Stainless Steel Flat and Round Bars

Melting and Casting:

Stainless steel flat and round bars are produced directly by melting and casting. All elements in chromium, nickel, molybdenum, and other alloying elements of raw iron ore are melted within the electric arc furnace in due proportion. It purifies and reconstitutes the composition in ladle refining, ultimately giving steel its desired chemical composition. From there, this steel is allowed to go directly into casts where it results in either square-sectioned for flat bars or circular-cross-sectioned billets for making round bars.

Hot Rolling Process:

These billets are then heated to some high temperature above the recrystallization point and passed through a hot rolling mill. For example, the hot rolled flat bars are made from billets formed by using flat rolls, while round bars take cylindrical rolls, which help in further refining the grain structure of the metal, thus greatly improving strength and machinability.

Cold Drawing (Optional):

Certain applications demand cold drawing of bars. Further reduction of the pre-rolled bars to room temperature offers better surface finish and dimensional accuracy. This step is, therefore, optional for the smooth and precision-demanding products.

Heat Treatment:

Annealing or heat treatment of the bars helps to get enhanced mechanical properties of the bars through increased stress relief and ductility, which increases the usability and life span of the finished product.

Cutting and Finishing:

The final operation is the cutting of the bars to exact lengths and then polishing or coating for a smooth finish. The flat and round bars are inspected on the surface before being prepared for packaging and shipment.

Applications of Stainless Steel Flat and Round Bars as Per Different Grades

Grade 304 Stainless Steel:

Grade 304 is the most popular and versatile grade of stainless steel for flat and round bars. It has excellent corrosion resistance and good machinability, which makes it perfect for use in food processing equipment, kitchen utensils, and decoration. In commercial kitchens, grade 304 flat bars are in widespread use on countertops and structural supports, but round bars are generally used for shafts and fasteners. The hygienic, non-reactive surface of the grade makes it especially suitable for food-grade environments, ensuring safety and reliability in these settings.

Grade 316 Stainless Steel:

Grade 316 stainless steel is suitable in aggressive environments, such as marine and chemical processing. It contains a high molybdenum content, which enhances chloride resistance and strength. Flat bars grade 316 are used in the marine industries as brackets and supports. Round bars are highly used in the manufacture of components, like valves and pump shafts, in chemical plants and desalination systems.

Grade 410 Stainless Steel:

Grade 410 stainless steel has high strength and moderate corrosion resistance; hence, they are widely used in automotive and machinery parts. Flat bars are normally used in transmission systems and heavy-duty brackets, while round bars grade 410 can be used for gears, shafts, and cutting tools that give wear resistance and toughness.

Grade 430 Stainless Steel:

The largest application for grade 430 stainless steel is in decorative and low-corrosion environments. Flat bars are best suited to applications such as architectural trim and paneling, while the round bars are better suited to appliances and light-duty mechanical components, where a balance of functionality and aesthetic appeal is required.

Grade 321 Stainless Steel:

Grade 321 stainless steel is known for its resistance to high temperatures. Flat bars are used in heat exchangers and boiler systems, and the round bars are widely used in the production of components for aerospace and thermal systems.

Summary Table of Applications by Grade

| Grade | Primary Applications |

| 304 | Construction, food processing, automotive, plumbing. |

| 316 | Marine, chemical, medical, energy sector. |

| 410 | Automotive, aerospace, industrial tools, defense. |

| 430 | Appliances, decorative trims, furniture, retail displays. |

| 321 | Aerospace, power plants, high-temperature systems. |

| 201 | Furniture, interior design, retail, transport. |

| 310 | Furnaces, petrochemical, energy sector, high heat areas. |

| Duplex | Oil & gas, marine, desalination, structural engineering. |

Advantages of Stainless Steel Flat and Round Bars

Corrosion Resistance: The most evident benefit to both the stainless steel flat and round bars is the great corrosion resistance. The high Chromium content saves the material from rust and oxidization, hence ideal in extreme environments such as marine, chemical and industrial setups. The flat bars find their way into structural supports while the round bars are used in rotating components that are exposed to moisture and chemicals.

Strength and Durability: Stainless steel flat and round bars are much applied for heavy-duty load-supporting applications because of their great tensile strength and toughness. The high resistance to wear and long service life allow them to be good at performing applications where the product will see prolonged service in machinery, construction, and infrastructure. Accurate dimensions of round bars and flat bars contribute to the performance of them, being reliable and efficient under harsh environments.

Versatility and Aesthetic Appeal: These versatile of stainless steel flat and round bars serve both industrial and decorative purposes. Flat bars are greatly used in architectural designs, railings, and frameworks, while the round shape is preferred in the manufacture of shafts, tools, and fasteners. The polished finish, along with a modern look coupled with all intrinsic characteristics of stainless steel, was and continues to be very instrumental in their choice, where functionality and aesthetics are of equal importance.

Limitations of Stainless Steel Flat and Round Bars

High Cost: The major limitation of stainless steel flat and round bars is the high upfront cost, which can be a barrier to small-scale industries. Production of stainless steel requires expensive raw materials and complicated processing, which makes the product much more expensive than other materials. This makes them less accessible for budget-sensitive projects.

Specialized Equipment Requirement: The cutting, welding, and fabrication of stainless steel flat and round bars require specialized tools and expertise. Improper handling can cause cracks and performance issues. This also increases processing costs and time.

Density and Weight: The high density of stainless steel makes its bars heavy, which creates difficulty in transportation and installation. Handling large-diameter round bars or thick flat bars requires additional equipment, which further increases project costs.

Properties of Stainless Steel Flat and Round Bars as per Grades

Grade 304 Stainless Steel: Grade 304 is the most commonly used stainless steel, process combining excellent corrosion resistance and formability. The main applications of flat and round bars of this grade include food processing, kitchen equipment, and decoration. Combining lightness with strength, Grade 304 stainless steel flat and round bars are versatile; thus, they may be put to many different uses. They also show very good machinability and weldability ideal for fabrication and reformation. Still, this grade could be susceptible to pitting corrosion in high chloride concentration environments.

Grade 316 Stainless Steel: Grade 316 stainless steel flat and round bars has excellent corrosion resistance and, therefore, is suited for applications in the marine and chemical processing industries. This grade incorporates molybdenum, which provides excellent performance even in high-chloride environments. They are in wide use as shafts and marine hardware, while flat bars for industrial tanks and structural components. The high heat resistance of Grade 316 makes it useful for critical applications.

Grade 410 Stainless Steel: Grade 410 is a martensitic stainless steel renowned for its hardness and wear resistance. Bars of this grade are used to make tools, knives, and wear-resistant components. It provides high strength but has slightly lower corrosion resistance than 304 and 316.

Grade 303 Stainless Steel: Grade 303 stainless steel flat and round bars is known for its good machinability. Round and flat bars of this grade are used in the manufacture of precision components, such as screws and gears. It has moderate strength and good corrosion resistance but is not as suitable for welding.

Grade 321 Stainless Steel: Grade 321 is ideal for high-temperature applications because it provides resistance against carbide precipitation. Flat and round bars are used in heat exchangers, exhaust systems, and aerospace components. Its thermal stability and durability are important in high-performance environments.

Conclusion

In most industrial and commercial applications, stainless steel flat and round bars are indispensable. Versatility, outstanding properties—including resistance to corrosion, strength, and durability—make them apt for a variety of industries. Other grades available include 304, 316, and 410, where each grade provides solutions tailor-made for specific applications. The 304 grade is used in general-purpose applications, though the better corrosion resistance exhibited by the 316 grade makes it more preferable in the marine and chemical industries.

Flat bars are great for structural support and frames, while round bars are used to a great extent in precision machining, manufacturing of fasteners, and shafts. Machinability and weldability make fabrication and assembly easier and more efficient.

While its high up-front cost and the availability of certain grades can be problematic, long-term performance and low maintenance cost make them cost-effective. Grade selection, proper application-specific customization ensures the projects are both efficient and reliable. Due to its versatility and good mechanical properties, stainless steel flat and round bars are a must-have for modern engineering and manufacturing needs and become an indispensable material in several industries.

For more details and insights about steel visit WiserBolt.com!

Pingback: STAINLESS STEEL WIRE:- Manufacturing to Applications