Cut to Length (CTL) machine line is a modern industrial system meant for cutting metal coils into required dimensions. The main purpose of this system is to cut metal sheets into desired length and width, which are further used in fabrication and manufacturing processes. Cut to Length lines are highly efficient and precise, saving time and cost for the industries.

Cut to Length machines can work with coils of steel, aluminum, copper, and other metals. The main steps in this system include uncoiling, levelling, and cutting. The final output is high-quality metal sheets used in the construction, automotive, appliances, and heavy machinery sectors.

These are high-speed machines with automation, hence making the production process efficient. The modular design allows customization for different applications. CTL lines are in use across a range of industries where precision and high-volume production are required.

One of the key benefits of CTL machine lines is waste reduction, with increased production speed and constant quality. They are simply a must for modern manufacturing.

Key Components of Cut to Length Machine Line & It’s Working

Un-coiler:

The main function of the un-coiler is to firmly hold the metal coil and uncoil it. This part ensures that the coil unwinds smoothly without wrinkles or dents. Heavy-duty un-coilers have hydraulic or motorized systems that maintain even tension, making them efficient in operation.

Leveler:

The leveler is the one that flattens the sheet. In the coiled metal sheets, there is stress and unevenness that the leveler takes off. It produces smooth and defect-free sheets using precision rollers and adjustable pressure.

Shearing Unit:

The shearing unit is the right cutting system that shears sheets to the needed length. Advanced shears are designed for high-speed and precision operation to ensure minimum wastage and consistency in size.

Stacker:

A stacker arranges cut sheets in order. The automated stacker makes production lines more efficient, and neatly stacks the sheets, which then eases the process of transportation and handling.

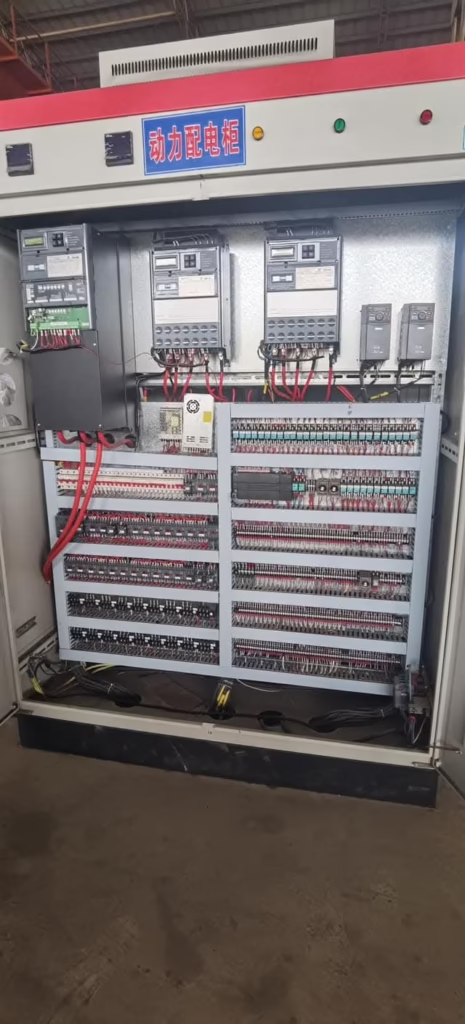

Control System (Automation and Monitoring):

The CTL machine control system is used for the automation and observation of orders. Advanced control panels are equipped with sensors and programmable logic controllers for high precision and operator-friendly functionality.

Features of Cut to Length Machine Line

High-Speed Operation: Cut to Length machines provide high-speed cutting capabilities, which are very ideal in high-volume production. Advanced systems run at speeds of 100 meters per minute or more to save time and increase productivity.

Precision Cutting: Cut to length machines cut sheets to accurate length and width with zero errors. Advanced control systems and servo-driven mechanisms maintain high precision, which is very important in critical industries.

Multi-Material Handling: The machine can work with a variety of metals, including carbon steel, aluminum, and copper. In the CTL line, various thicknesses and grades of sheets could be adjusted to, hence being very versatile.

Efficient Leveling System: Units in this series have built-in leveling units that ensure sheets are absolutely flat and free of tension. This enhances the quality of the sheet further, directly influencing the performance of the end product.

User-Friendly Automation: The Cut to length lines are designed with advanced control systems and automation, enabling easy operation and monitoring. PLCs and HMIs simplify the control of the process by the operator in order to ensure efficiency and safety.

Applications of Cut to Length Machine Line

Automotive Industry:

Cut-to-Length machines prepare high-precision stainless steel and aluminum sheets used in making parts of automobiles, such as car panels and structural components. Their accuracy and consistency ensure vehicle durability and safety.

Construction Sector:

CTL lines are used in the production of roofing, flooring, and cladding materials for construction projects. These machines provide customized sizes and thicknesses that perfectly fit architectural requirements.

Manufacturing of Appliances:

Home appliances, like refrigerators and washing machines, are made from Cut-to-Length sheets. CTL lines produce energy-saving, defect-free sheets, giving smooth finishes and consistent performance.

Heavy Machinery:

Heavy machinery, including cranes and parts for industrial machines, needs high-strength sheets. CTL lines cut and process, with perfect accuracy, robust materials such as thick steel.

Electrical Equipment:

Precision-cut metal sheets are required for the fabrication of electrical panels and enclosures. CTL machines ensure uniform size and smooth edges, which further facilitates insulation and assembly.

Advantages of Cut to Length Machine Line

High Precision: CTL machines cut metal sheets to exact length and width for uniformity and accuracy. This is very essential in making quality products that will pass industry specifications.

Cost Efficiency: Their high-speed operation, coupled with minimal wastage, makes them cost-effective. They are designed especially for large-scale production, which reduces material and labor costs.

Versatility: CTL machines are adapted for cutting different metals such as steel, aluminum, and copper of various thicknesses; hence, they are versatile and can be used in many industries.

Increased productivity: With automation and high-speed capabilities, CTL machines will drastically improve production speed, which comes in handy when dealing with tight deadlines.

Consistency: CTL lines ensure the repeatability of accuracy and leveling; hence, sheets are stress-free and smooth with consistent quality, even in big batches.

Conclusion

The cut to length machine line has been one of the important units in the steel processing industry in the production of high-precision and quality steel sheets. Versatility makes the CTL very effective and handy in construction, automobile, and appliance industries. If your operations require flat sheets, then a CTL is an investment that will raise both productivity and quality.