Slitting machine line is a demanding machinery in the steel processing industry that cuts steel coils into strips of small, uniform width. This process is called “slitting” and this machinery increases the flexibility of steel for industrial applications. Steel manufacturers produce steel coils in fixed widths such as 900mm, 1200mm, 1500mm, 2500mm and to cut them into smaller widths they require slitting machine line.

Let’s know in detail about the features, components, working process and applications of slitting machine line.

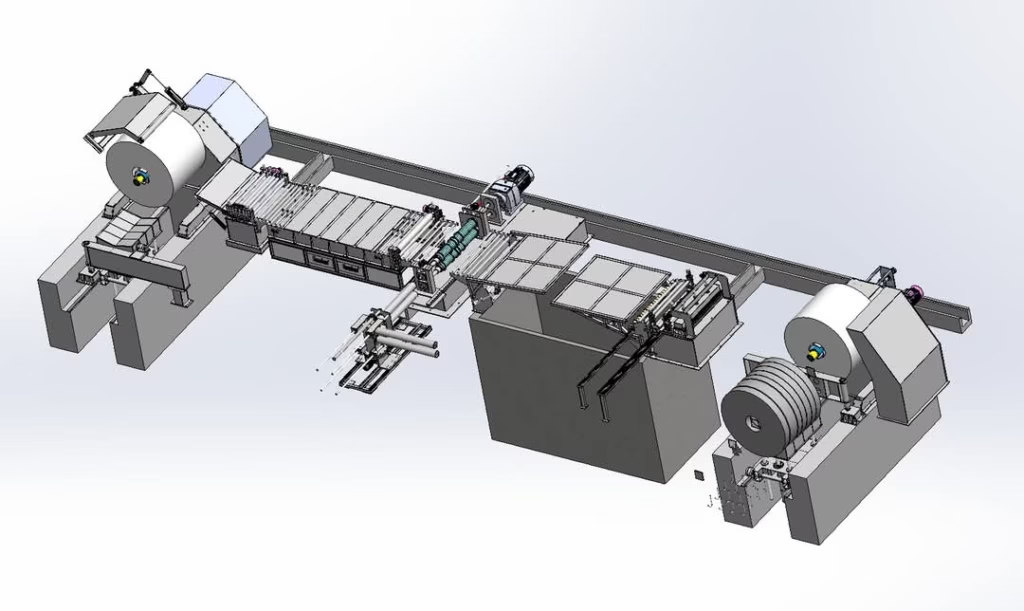

Slitting Machine Line Key Components and their working process

Un-coiler: Holds the steel coil and prepares it for unwinding. Ensures smooth feeding, which is essential for the slitting process. Large steel coils are loaded onto the un-coiler and un-winded.

Slitter Head: It is the major cutting section. The sharp blades of the slitter head shear the steel to a narrow strip in the needed width. Slitter head has the assembly for mounting in which the cutting wheels and space rings are taken along with arbor shafts. The shaft has high-strength material support, so there should not arise any load or stress. The cutting wheels and spacer on the slitter head are set to the desired strip width. The cutting wheels bear down on the steel coil with a shearing action, hence cutting the material into narrow strips.

Tensioner: It holds the steel strips with proper alignment and uniform tension. Prevents the strips from getting tangled during slitting.

Re-coiler: Used in rolling the slitted strips in order to get a neat form. Prepares final output of the product, compact and handy to handle. Cut strips are tightly rolled on re-coiler, ready for further processing into, say an ERW tube mill where pipes by welding are manufactured.

Control Panel: Monitors and controls machine speed, tension, and alignment. Automation ensures precision and efficiency.

Material of Cutting Wheels

The material of cutting wheels determines their durability, sharpness, and efficiency.

High-Speed Steel (HSS): Commonly used due to its high wear resistance and toughness. Ideal for heavy-duty applications due to heat resistance properties.

Carbide-Tipped Blade: Extremely hard, wear-resistant, suitable for precision cutting.

Tool Steel: Has the ability to resist impact and maintain a sharp edge and is preferred for medium-duty applications

Alloy Steel: For strength and corrosion resistance. Cost-effective and suitable for general-purpose cutting

Features of Slitting Machine Line

High Precision: Cutting of steel coils requires smooth edges of large narrow strips and ensures uniform width.

Versatility: Can process materials such as carbon steel, stainless steel, galvanized steel, and aluminum.

Automation: Advanced control systems make it speedy and effective.

Customizability: The slit capability of steel coils of any size and thickness.

Durability: Heavy-duty components and robust design ensure long-term reliability.

Applications of Slitting Machine Line

Automotive Industry:

Thin steel strips used in car bodies, frames, and other components.

Construction Materials:

Steel strips are used for roofing sheets, structural components, and insulation materials.

Electrical Components:

Transformers, motors, and other electrical equipment require precision strips.

Packaging Industry:

Slitted steel is used to make strapping bands and other packaging materials.

Steel Pipe Manufacturing:

Steel strips are used as raw material for ERW tube mills.

Advantages of Slitting Machine Line

Efficiency: Has the capacity to accurately slit large coils in a single pass.

Cost-Effectiveness: Automation and high-speed process reduce labor cost and time. The speed of the machine depends on the thickness, for example, for thicknesses of 0.5 mm to 3 mm, the line speed is approximately 250 meters per minute and for thicknesses up to 8 mm, it is 80 meters per minute.

Waste Reduction: Precise cutting minimizes material wastage.

Improved Product Quality: Produces strips with smooth edges and consistent width, which enhances the quality of the final product.

Conclusion

Slitting machine line is an indispensable tool for the steel processing industry. This machinery not only makes the production process efficient, but also helps in making high-quality steel products. If your business involves processing steel coils, then a slitting machine line is an essential investment that will streamline your operations and increase productivity.