Introduction to Hot Rolled Steel

Hot Rolled Steel: This is a type of steel that, for manufacture, is heated to high temperatures above its crystallization point of approximately 926°C to 1400°C. The temperature is so high that the steel can easily be formed into any form or shape, which makes it cost-effective and versatile for many applications, from building structures to the frames of cars. Hot Rolled Steel (HR STEEL) is very important in our lives. Its strength, ease of production, and adaptability make it the foundation material in many industries on which we depend every day.

What is Hot Rolled Steel?

HR Steel is made in a process where the steel is heated above the recrystallization temperature and then rolled into bars, sheets, and coils. Steps are as follows:

Heating: The steel slabs/billet/ingot is heated to high temperatures to make it soft and hence easy to roll.

Rolling: Pass the steel through rollers after heating, to achieve a thickness or a shape of desired form.

Cooling: After rolling, the steel is allowed to cool at room temperature, due to which there are some defects in the surface finish but still it is functional and durable.

Unlike cold rolled steel, HR Steel is not re-rolled at room temperature, which is why it has a more natural finish and less expensive.

Key Properties of Hot Rolled Steel

Hot Rolled Steel is known for properties such as:

• Strength and Durability: HR Steel is quite strong and can withstand heavy loads, due to which it is very useful in structural applications.

• Cost-Effectiveness: Its manufacturing process is very simple due to which it is cheaper than other materials.

• Flexibility: It can be formed into any size and shape through hot rolling process, due to which it is ideal for industrial uses.

• High Ductility: It has good flexibility and can be easily bent or shaped, which makes it versatile for applications where formability is required.

Why Hot Rolled Steel is Important in Our Life

Hot Rolled steel has touched almost every single aspect of our modern life. Now, let us find out why this material is so vital:

a. Construction and Infrastructure

HHR Steel is a material that becomes the basic component in construction for buildings, bridges, and many structures.

Structural Integrity: Strength makes HR Steel perfect for beams, columns, and girders.

Versatility: It can be used in different shapes and structural elements.

Cost Efficiency: It is inexpensive, so it is the first choice in large-scale construction projects.

Without HR Steel, it will be very difficult and costly to build durable and affordable buildings, roads, and bridges

b. Manufacturing Industry

HR Steel is applied to the manufacture of a huge number of machinery, equipment, and parts in industry.

Heavy Machinery: HR Steel is common in the frames and other parts of tractors, bulldozers, and similar heavy machinery due to its great strength and durability.

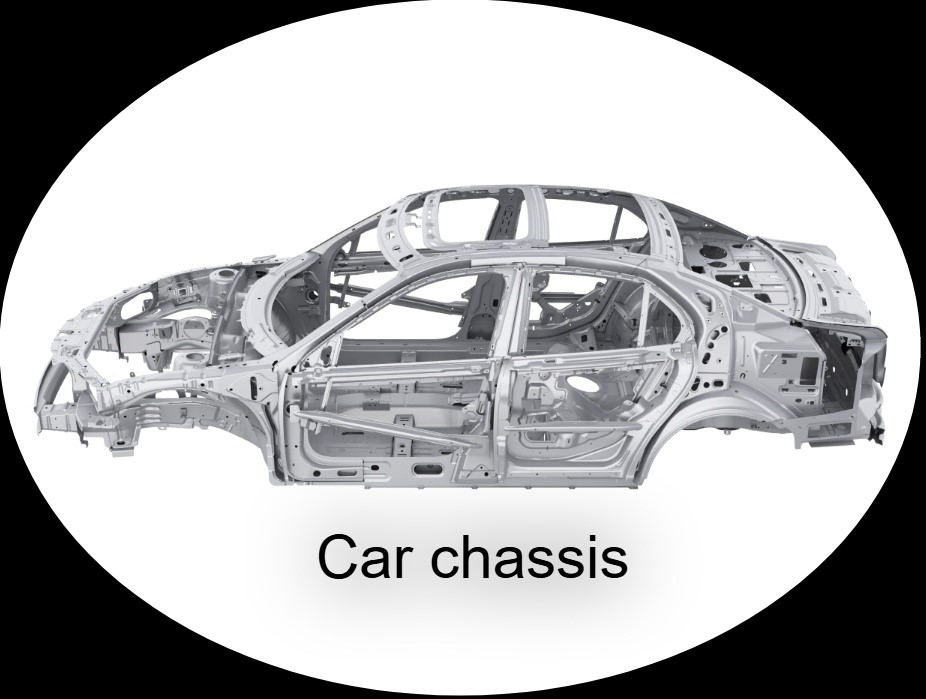

Automotive Frames: HR Steel is used in the automotive industry in the chassis, frames, and body parts of vehicles where strength is important for safety and durability.

Industrial Equipment: HR Steel is used in industrial machinery, tools, and mechanical components where there is a requirement for both strength and formability.

c. Everyday Appliances and Products

HR Steel is part of the home—from kitchen appliances to furniture.

Household Appliances: The basic components of most washing machines, dryers, refrigerators, and ovens standardly contain HR Steel for strength and durability.

Furniture: HR Steel is in office furniture, desks, file cabinets, and shelving for strength and stability.

Decorative Items: Many decorative items and fixtures also use HR Steel, which may be coated or painted to suit aesthetic needs.

d. Transportation Infrastructure

Hot Rolled Steel plays a vital role in the transportation sector for both land and rail transport infrastructure.

Rail Tracks: Railways use HR Steel for tracks that have to withstand high loads and extreme environment.

Shipping Containers: HR Steel can provide the strength and durability required by shipping containers, which are designed to withstand rough handling in tough environments.

Bridges and Roadways: HR Steel is one of the preferred materials used in making bridge frameworks and road supports because it can bear weight and weather.

Manufacturing Process of Hot Rolled Steel

The manufacturing process of Hot Rolled Steel is efficient and quick, making it possible to produce large quantities. Here are the main steps:

Raw Material Preparation:

The raw materials required for hot rolled steel production include iron ore, coal, and limestone. First, iron ore is put into a blast furnace and smelted with a combination of coke, refined coal, with limestone added to it. It further turns molten iron free from all sorts of impurities. Then, this molten iron is further refined to make steel. During this stage, alloying elements such as manganese, chromium, and nickel are added into it, due to which this steel attains better properties.

Castings:

The refined molten steel is transferred to a casting machine, which shapes it into slabs, blooms, or billets. These semi-finished products now become the basic material for hot rolled steel production. Coming out of the caster, it cools down slowly to avoid possible stresses and faults.

Heating:

After casting, the slabs are heated in a reheating furnace at a temperature of 1100°C to 1250°C. This high temperature softens the steel, which is very necessary for the rolling process. It is important that there should be uniform temperature at the heating stage since this will ensure the quality of the material is maintained.

Rolling:

The heated slabs are passed through a rolling mill where their thickness and width are adjusted. At this stage, the original thickness of the steel is reduced to the desired dimensions. During the rolling process, the mechanical properties of the steel also improve such as strength and ductility. The process is very fast and used to make either steel sheets or coils.

Cooling:

After rolling, the hot rolled steel is immediately quenched in a laminar flow water. This process of rapid cooling increases the surface properties as well as the strength of the steel. The controlled cooling refines the grain size and structure of the steel and hence increases the life span of the product.

Coiling and Storage:

During the last stage, the hot rolled steel is rolled into large coils or cut into flat sheets. These products are ready for transportation and storage in industries. It is very necessary that the quality and surface finish of the product be maintained during coiling and storage.

Advantages of Hot Rolled Steel

Some of the advantages of Hot Rolled Steel make it indispensable:

Affordability: The hot rolling process is simpler, so the overall cost is lower.

Strength: It can withstand heavy loads and harsh conditions.

Versatility: HR Steel may be shaped and sized in various ways, hence its usefulness in many applications.

Quick Production: The process is fast, enabling manufacturers to meet large demands efficiently.

Those benefits make HR Steel the first choice for many large-scale projects and industrial applications.

Limitations of Hot Rolled Steel

While HR Steel has so many advantages, it also presents some limitations.

Surface Finish: The surface finish is not as smooth as cold-rolled steel, which can prove to be a disadvantage in aesthetic applications.

Less precise: Hot rolling produces looser dimensional tolerances, which makes it less desirable for high-precision parts.

Corrosion Susceptibility: If left uncoated, HR Steel is more prone to rust and corrosion.

However, most of the above disadvantages could be compensated for by further processing, such as cold rolling of steel, coating, or galvanizing, to make HR Steel even more versatile.

Future of Hot Rolled Steel

It has been in line with developments in technology; thus, HR Steel continues to be much more efficient and sustainable. The making of it greener incorporates energy-efficient furnaces, better rolling techniques, and eco-friendly coatings. With all this in the industrial segment pushing towards sustainable solutions, HR Steel is and will always remain paramount for modern-day infrastructure and manufacturing.

Conclusion

Hot Rolled Steel is a fundamental material with a huge impact on our lives, from the buildings in which we live and work to the vehicles we travel in and the products we use daily. Its strength, affordability, and versatility make it invaluable in many different industries. It is an industry that will continue to grow with technology and sustainability initiatives.

Pingback: HOT ROLLED CARBON STEEL RECYCLING - STEEL PRODUCT INFO.

Great job

Pingback: TMT 500 STEEL BARS:- WHY WE USE IT IN CONSTRUCTION

Pingback: HOT ROLLED CARBON STEEL PIPES - STEEL PRODUCT INFO.

Pingback: WELDED STEEL PIPES:- A COMPLETE GUIDE

Pingback: What is HOT ROLLING MILL? - STEEL PRODUCT INFO.

Pingback: Cut to Length Machine Line (CTL) - WISERBOLT

Pingback: HOT ROLLED CARBON STEEL RECYCLING

Pingback: HOT ROLLED CARBON STEEL PIPES

Pingback: WELDED STEEL PIPES:- A COMPLETE GUIDE